How to Create a Good STL File from Your Solid Modeling Software

How to Create a Good STL File from Your Solid Modeling Software

A Good "STL"... what's that?

STL shows the triangled based mesh of a 3D Design. What's the difference between a CAD and an STL file?

A CAD is defined by its parameters, whereas an STL file is defined by triangles made of vertices and normals. The CAD file is therefore more precise, whereas the STL is a close approximation. CAD is focused on designing for traditional manufacturing, and does not include information on the outside and inside of the part. An STL does include this important information, which is why it became the standard file format for 3D printing.

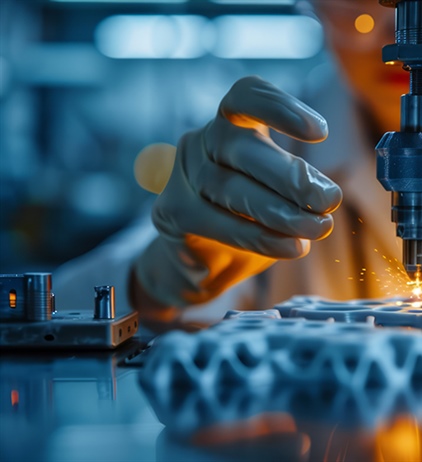

Quality Control in the Age of Smart Manufacturing

Quality Control in the Age of Smart Manufacturing

When Speed Meets (or Misses) Standards

In an era where "smart" and "fast" are the darlings of manufacturing buzzwords, we need to have an honest conversation about quality control.

As someone deeply embedded in the world of precision manufacturing at SICAM, I've watched the evolution of quality control from meticulous human inspection to AI-powered quality assurance – and not all that glitters is...