Design for Consistency: Best Practices for Engineering Low-Volume Parts Using MJF vs FFF 3D Printing

Design for Consistency: Best Practices for Engineering Low-Volume Parts Using MJF vs FFF 3D Printing

When you're producing 5 to 500 parts using additive manufacturing, consistency becomes everything. Your customers expect the 50th part to perform exactly like the first one. But achieving this consistency requires understanding how Multi Jet Fusion (MJF) and Fused Filament Fabrication (FFF) technologies work: and more importantly, how to design for their strengths and limitations.

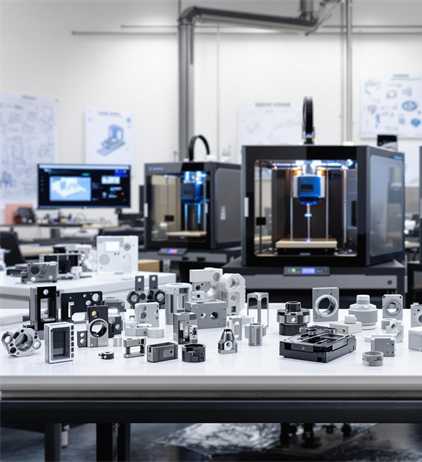

FFF 3D Printing: How Mechanical Engineers Are Rewriting the Rules of Innovation

Why Forward-Thinking Engineers Choose FFF—and the Right Partner—to Bring Complex Ideas to Life

If you’re a mechanical design engineer, you know the pressure—move fast, cut weight, hit tolerance, and get that prototype off your screen and into the real world, fast. Whether you’re developing aerospace brackets, EV battery components, or automation tooling, the gap between concept and reality can make or break your project. You’re always looking for a smarter,...