Design for Consistency: Best Practices for Engineering Low-Volume Parts Using MJF vs FFF 3D Printing

When you're producing 5 to 500 parts using additive manufacturing, consistency becomes everything. Your customers expect the 50th part to perform exactly like the first one. But achieving this consistency requires understanding how Multi Jet Fusion (MJF) and Fused Filament Fabrication (FFF) technologies work: and more importantly, how to design for their strengths and limitations.

Why Consistency Matters in Low-Volume Production

Low-volume production sits in a unique sweet spot. You're past the prototype stage where "good enough" works, but you're not at the volumes that justify injection molding tooling. Your parts need to function reliably, fit consistently, and look professional across the entire production run.

The challenge is that 3D printing technologies behave differently than traditional manufacturing. Each technology has its own quirks that can introduce variations if you don't design with them in mind.

MJF vs FFF: The Fundamentals That Affect Consistency

Multi Jet Fusion uses a powder bed where inkjet heads selectively apply fusing and detailing agents to nylon powder. The entire build chamber then gets heated uniformly, fusing the powder into solid parts. This process happens layer by layer, but the heating is applied to the whole layer at once.

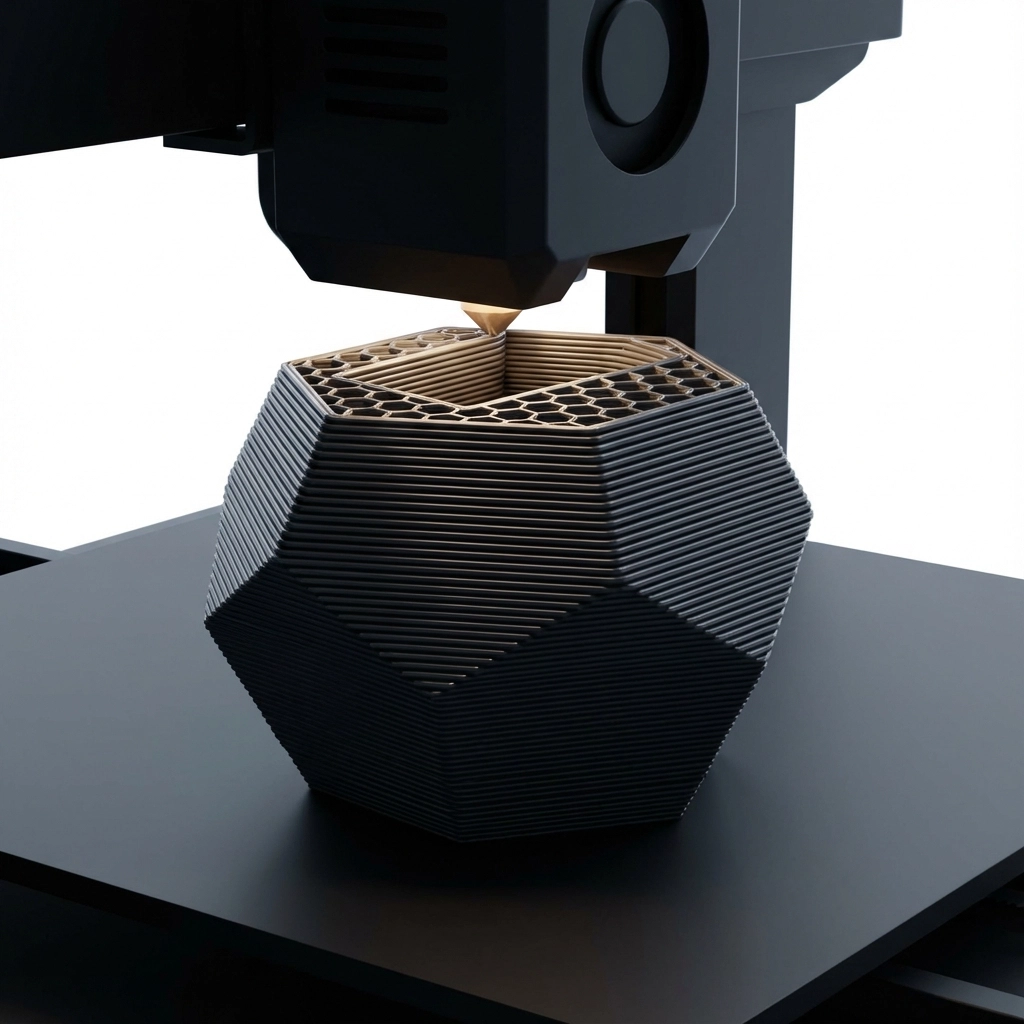

FFF (also called FDM) works by melting plastic filament and extruding it through a heated nozzle, building parts one line at a time. Each line must bond to the previous one, creating a part through thousands of tiny welds.

These fundamental differences create very different consistency profiles. MJF parts come out with uniform properties in all directions because the powder fuses uniformly. FFF parts are inherently directional: they're stronger along the print lines than between layers.

Material Properties: The Foundation of Consistency

The biggest consistency difference between MJF and FFF comes down to material properties. MJF produces isotropic parts, meaning they have the same mechanical properties regardless of how you orient them during printing or testing. A tensile test will give you similar results whether you pull the part along the X, Y, or Z axis.

FFF parts are anisotropic. They're typically strongest in the XY plane and weakest in the Z direction. This means identical parts printed in different orientations will have different mechanical properties. For functional parts, this variation can be the difference between success and failure.

MJF also delivers mechanical properties very close to injection-molded nylon. If you're familiar with how injection-molded parts behave, MJF parts will feel familiar. FFF properties vary more significantly depending on material choice, print settings, and environmental conditions during printing.

Surface Quality and Dimensional Accuracy

Surface finish consistency is where MJF really shines. Parts come out of the printer with smooth, uniform surfaces that need minimal post-processing. The layer lines are barely visible, and more importantly, they're consistent across the entire part and between parts in a production run.

FFF parts show visible layer lines that vary based on layer height, print speed, and material characteristics. While you can minimize these through careful settings, they'll never match MJF's consistency without significant post-processing.

Dimensional accuracy follows a similar pattern. MJF maintains tight tolerances (typically ±0.3mm) with excellent repeatability. When you print the same part multiple times, the dimensions stay consistent. FFF accuracy depends heavily on printer calibration, environmental conditions, and material shrinkage: all variables that can change between print runs.

Design Best Practices for MJF

Embrace Design Freedom: Since MJF doesn't need support structures, design with complex geometries confidently. The powder bed supports everything during printing, so overhangs, undercuts, and internal channels won't create consistency issues from support removal.

Optimize for Batch Production: MJF's build chamber allows you to pack multiple parts efficiently. Design parts that nest well together and take advantage of the full build volume. All parts in a single build experience identical processing conditions, maximizing consistency.

Design for Tight Tolerances: MJF can hold ±0.3mm tolerances reliably, so design with confidence. Features as small as 0.5mm wall thickness and 0.25mm minimum features will print consistently across your production run.

Minimize Post-Processing: Design knowing that parts will come out ready to use or with minimal finishing. This eliminates post-processing variations that could affect consistency between parts.

Consider Thermal Management: Thick sections can cause warping during the cooling process. Keep wall thicknesses consistent throughout your design, and use ribs or hollow sections for strength instead of solid thick areas.

Design Best Practices for FFF

Standardize Orientation: Since FFF properties depend on print orientation, establish a standard orientation for each part design. Document this orientation clearly so every production run uses the same setup. This single decision will do more for consistency than any other design choice.

Design Out Supports: Every support structure you remove creates a potential consistency issue. Design parts with 45-degree maximum overhangs where possible. Use bridging capabilities for small spans. Add draft angles to eliminate overhangs entirely.

Control Wall Thickness: Keep walls between 1.2mm and 3mm for optimal consistency. Thinner walls may not print reliably across different machines or materials. Thicker walls can cause cooling issues that create warping or dimensional variations.

Plan Material Strategy: Choose established materials with proven track records. PLA and PETG offer good consistency, while exotic materials may vary between manufacturers or even between spools from the same supplier.

Design for Layer Adhesion: Orient critical stress areas to take advantage of FFF's strongest direction: along the print lines rather than between layers. For cylindrical parts, print with the axis vertical to maximize strength in the circumferential direction.

Process Control for Consistency

MJF process control is largely built into the technology. The system manages powder distribution, agent application, and heating automatically. Your main variables are material quality and part packing strategy. Focus on using fresh powder and arranging parts to minimize thermal gradients across the build chamber.

FFF requires more active process control. Establish standard profiles for each material and stick to them. Control environmental conditions: temperature and humidity variations will affect part quality. Implement regular calibration schedules and use the same brand of filament throughout your production run.

Quality Control and Testing

For MJF, establish dimensional checks on the first part from each build and spot-check every 10th part. The process is stable enough that if the first part is good, the rest will be too.

FFF requires more frequent checking. Measure critical dimensions on every part initially, then move to sampling once you've established process stability. Pay special attention to parts printed on different machines or with different filament spools.

Making the Choice: MJF vs FFF for Your Application

Choose MJF when you need maximum consistency with minimal effort. The higher equipment cost pays for itself through reduced quality control, minimal post-processing, and predictable results. It's ideal for functional parts where mechanical properties matter and tolerances are tight.

Choose FFF when you have simpler geometries, larger part requirements, or need specific material properties not available in MJF. The lower equipment cost means you can implement redundancy: having multiple printers reduces the risk of production delays while maintaining consistency through standardized processes.

For low-volume production where consistency is critical, MJF generally delivers better results with less effort. But with proper design discipline and process control, FFF can achieve adequate consistency for many applications at a much lower initial investment.

The key is understanding your technology's behavior and designing accordingly. Whether you choose MJF or FFF, consistency comes from working with the technology's strengths rather than fighting against its limitations.

Ready to explore additive manufacturing options for your low-volume production needs? Check out our additive manufacturing capabilities or get a quote to discuss your specific requirements.

113