The Design Engineer's Guide to Qualifying AM Parts for Production

Additive manufacturing gives you incredible design freedom, but with that freedom comes variability...

So you've designed a killer part using additive manufacturing, and now your boss is asking, "Can we scale this to production?"

It's a question that makes a lot of design engineers pause. Moving from prototype to production-ready AM parts isn't just about hitting "print" a few hundred more times.

It requires a systematic qualification process to ensure every part meets your specs, consistently.

Let's walk through exactly how to qualify AM parts for production, so you can confidently answer that question with a resounding "yes."

Why Qualification Matters More Than You Think

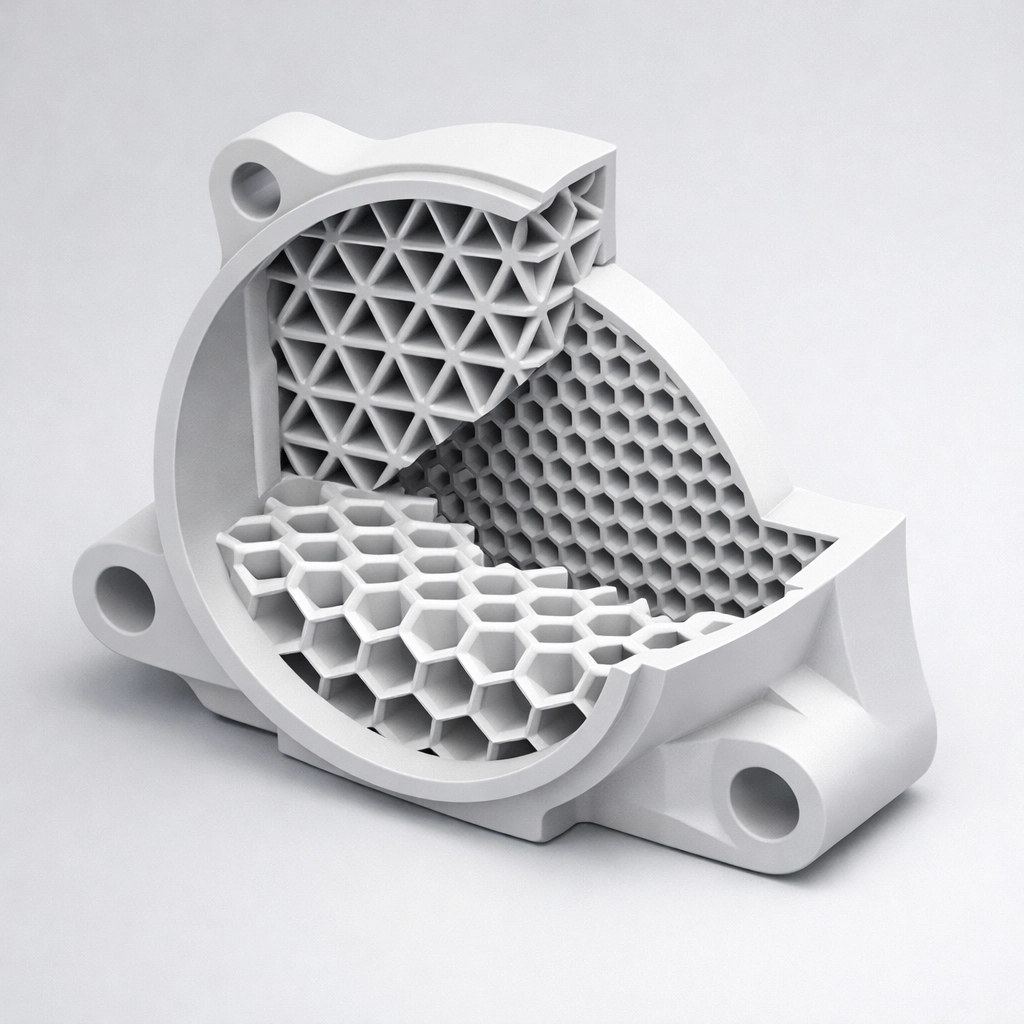

Here's the thing: additive manufacturing gives you incredible design freedom, but with that freedom comes variability. Unlike traditional manufacturing where you're working withAM predictable, homogeneous materials, AM builds parts layer by layer. That means thermal history, build orientation, and even where your part sits on the build plate can affect its properties.

Qualification isn't bureaucratic red tape, it's your insurance policy. It proves that your parts will perform as designed, batch after batch, no matter who's running the machine or when it was built.

The Four Pillars of AM Part Qualification

Think of a qualification as a four-legged stool. Miss one leg, and the whole thing collapses. Here's what you need to lock down:

1. Facility Qualification

Before you even think about your specific part, you need to know the production facility has its act together. This means verifying they have proper quality management systems in place, think ISO 9001 or AS9100 certifications.

At SICAM, our ISO-certified facility means we've already checked these boxes. We maintain documented procedures for machine maintenance, operator training, and statistical process control. It's the foundation everything else builds on.

Ask yourself: Does the facility have documented AM processes? How do they handle machine calibration? What's their training program look like? These aren't nice-to-haves, they're essentials.

2. Machine and Process Qualification

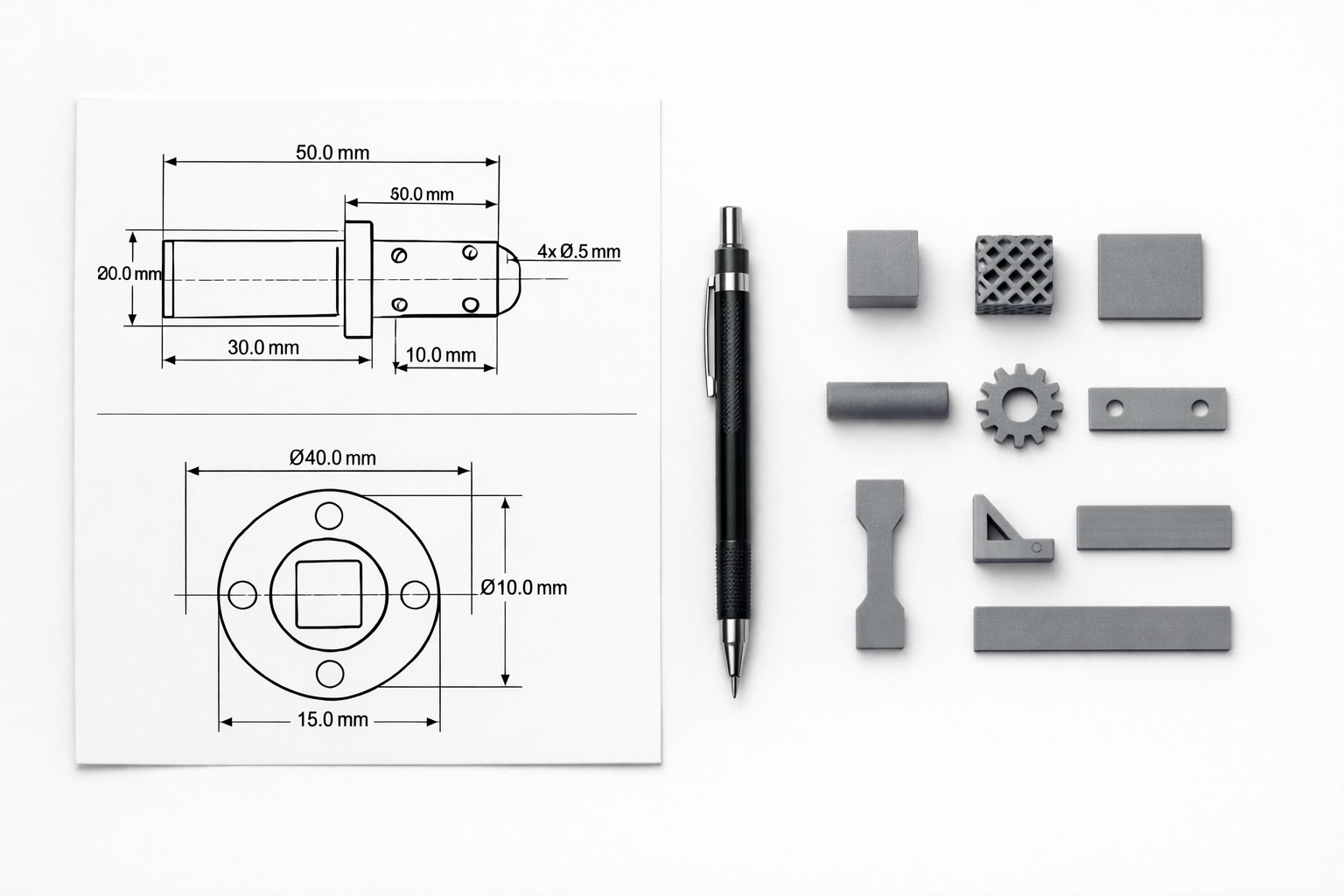

This is where you prove the machine can consistently produce parts that meet material specifications. Whether you're using MJF (Multi Jet Fusion), SLA (Stereolithography) or FFF (Fused Filament Fabrication), you'll need to run qualification builds that include test coupons alongside your actual parts.

These test coupons get put through the wringer, tensile testing, material analysis, and dimensional checks, to characterize the mechanical properties and understand material scatter.

For technologies like MJF, SLA, and FFF, this step is critical because powder-based processes have more variables than, say, traditional machining.

The goal? Demonstrate that the process is repeatable and capable of hitting your design requirements every single time.

3. Part Qualification

Now we're getting into your specific part. This phase involves manufacturing multiple builds in your production configuration, running them through all post-processing steps (heat treatment, surface finishing, whatever you need), and then testing them against your engineering requirements.

You'll need witness coupons for chemistry and microstructure analysis, dimensional inspection data, and potentially non-destructive testing like CT scanning or ultrasonic inspection. This is where you prove your design works in the real world, not just in CAD.

4. Lot Acceptance Testing

Once you've qualified the facility, process, and part design, you still need a way to verify each production lot meets specs. This is your ongoing quality gate.

You'll agree on factory acceptance tests with your manufacturing partner: tests that can be performed on each batch without destroying every part.

This might include dimensional checks, visual inspection, mechanical testing on sample parts, or witness coupons built alongside production parts.

The key is establishing clear pass/fail criteria upfront.

Design Requirements: Get Specific or Get Burned

Before you start the qualification, you need crystal-clear requirements documented. Vague specs like "it should be strong" won't cut it. You need to define:

- Loading conditions: What forces will the part see? Static? Dynamic? Cyclic?

- Operating environment: Temperature ranges, chemical exposure, humidity

- Interface requirements: How does it mate with other components?

- Expected service life: 100 cycles? 100,000 cycles?

- Consequence of failure: What happens if this part breaks?

Don't forget about factors you can't easily test, like long-term exposure to UV or hot/wet conditions. Build in appropriate safety margins for these unknowns.

AM-Specific Design Considerations

Qualifying parts for production also means your design needs to be AM-friendly. Here are the big ones:

Wall Thickness and Geometry: Both MJF and SLA have sweet spots for wall thickness (typically 1-3mm minimum). Too thin and you risk warping or incomplete fusion. Design with your process in mind.

Build Orientation: This affects surface finish, accuracy, and mechanical properties. Parts built vertically might have different strength characteristics than parts built horizontally.

Support Structures: Unlike FFF, SLA and MJF are self-supporting, but you still need to think about powder removal from internal channels and trapped volumes.

Consolidation Opportunities: One of AM's superpowers is assembly consolidation. Can you reduce your 12-part assembly to 3 parts? That's fewer things to qualify and fewer potential failure points.

Material Consistency: The Make-or-Break Factor

Here's where things get real: material consistency is everything in production AM. With technologies like SLA and MJF, you're working with powdered polymers like PA12 (nylon). These materials need consistent particle size distribution, moisture content, and powder refresh ratios to produce consistent parts.

A qualified supplier maintains tight control over:

- Powder sourcing: Using consistent material suppliers and lot traceability

- Powder management: Tracking refresh ratios and aging

- Environmental controls: Temperature and humidity monitoring in production areas

- Material testing: Regular validation of powder properties

At SICAM, we maintain detailed material certifications and can provide material test data with each production run. This traceability is crucial when you need to investigate any quality issues down the line.

The Approval vs. Certification Distinction

Here's something that trips people up: approval and certification aren't the same thing.

Approval means your part design, the chosen material, and the manufacturing facility/process have been evaluated and meet functional requirements. It's the green light for production.

Certification means individual production parts or lots have been inspected and confirmed to meet the approved specifications. It's your ongoing verification.

Think of approval as qualifying for the race, and certification as verifying your lap times.

Non-Destructive Testing: Your Secret Weapon

When you're qualifying critical parts, non-destructive testing (NDT) methods are worth their weight in gold. CT scanning can reveal internal voids or density variations without destroying parts. Ultrasonic testing can detect delamination. Dye penetrant inspection catches surface cracks.

The beauty of NDT is that you can inspect actual production parts, not just test coupons. For high-value or safety-critical components, this extra layer of verification is often worth the investment.

Process Variation: Plan for It

Even with tight controls, AM processes have inherent variation. Build location on the platform, thermal history during the build, and even subtle differences between machines can affect part properties.

Smart design engineers account for this by:

- Establishing a "process box" that defines acceptable variation ranges

- Building in appropriate design margins

- Specifying critical dimensions and tolerances clearly

- Working with manufacturing partners to understand and minimize variation sources

Your Action Plan

Ready to get started? Here's your roadmap:

- Document your requirements in painful detail before talking to manufacturers

- Select a qualified manufacturing partner (like SICAM) with proper certifications and documented processes

- Develop a test plan covering facility, process, and part qualification

- Run qualification builds with witness coupons and full testing

- Establish lot acceptance criteria for ongoing production

- Maintain documentation of everything: seriously, everything

The Bottom Line

Qualifying AM parts for production isn't a quick checkbox exercise, but it doesn't have to be overwhelming. By following a systematic approach: facility qualification, process qualification, part qualification, and lot acceptance testing: you'll build confidence that your parts will perform as designed.

The key is partnership. Work with a manufacturing partner who understands qualification requirements and has the systems, certifications, and experience to support you through the process.

Ready to qualify your next AM part for production? Get in touch with our team to discuss your specific requirements and develop a qualification plan that works for your application.

5