From Prototype to Production: The SICAM Approach to Rapid, Reliable Parts

The Manufacturing Gap: Why Going from Prototype to Production is Complicated

If you've ever tried to bring a product to market, you know the journey from brilliant idea to mass-produced reality is filled with obstacles. The path from prototype to production is where many great concepts stall or fail entirely. According to industry research, nearly 70% of new product initiatives face significant delays during this critical transition phase.

At SICAM, we've spent over three decades perfecting this transition, turning what's typically a manufacturing headache into a streamlined process. So what makes this leap so challenging, and how have we cracked the code?

The Prototype-Production Paradox

Prototypes and production parts serve fundamentally different purposes:

- Prototypes are typically one-offs, created to validate form, fit, and function

- Production parts must be repeatable, cost-effective, and manufacturable at scale

- Materials often differ between prototyping and final production

- Tolerances that work for a prototype might be impossible or prohibitively expensive at scale

This disconnect creates what we call the "prototype-production paradox" – a design that works perfectly as a prototype may be fundamentally flawed from a manufacturing standpoint.

The SICAM Solution: An End-to-End Approach

What sets SICAM apart is our comprehensive approach that bridges this gap by design. Rather than treating prototyping and production as separate processes handled by different teams (or worse, different vendors), we've developed an integrated methodology that considers the entire product lifecycle from day one.

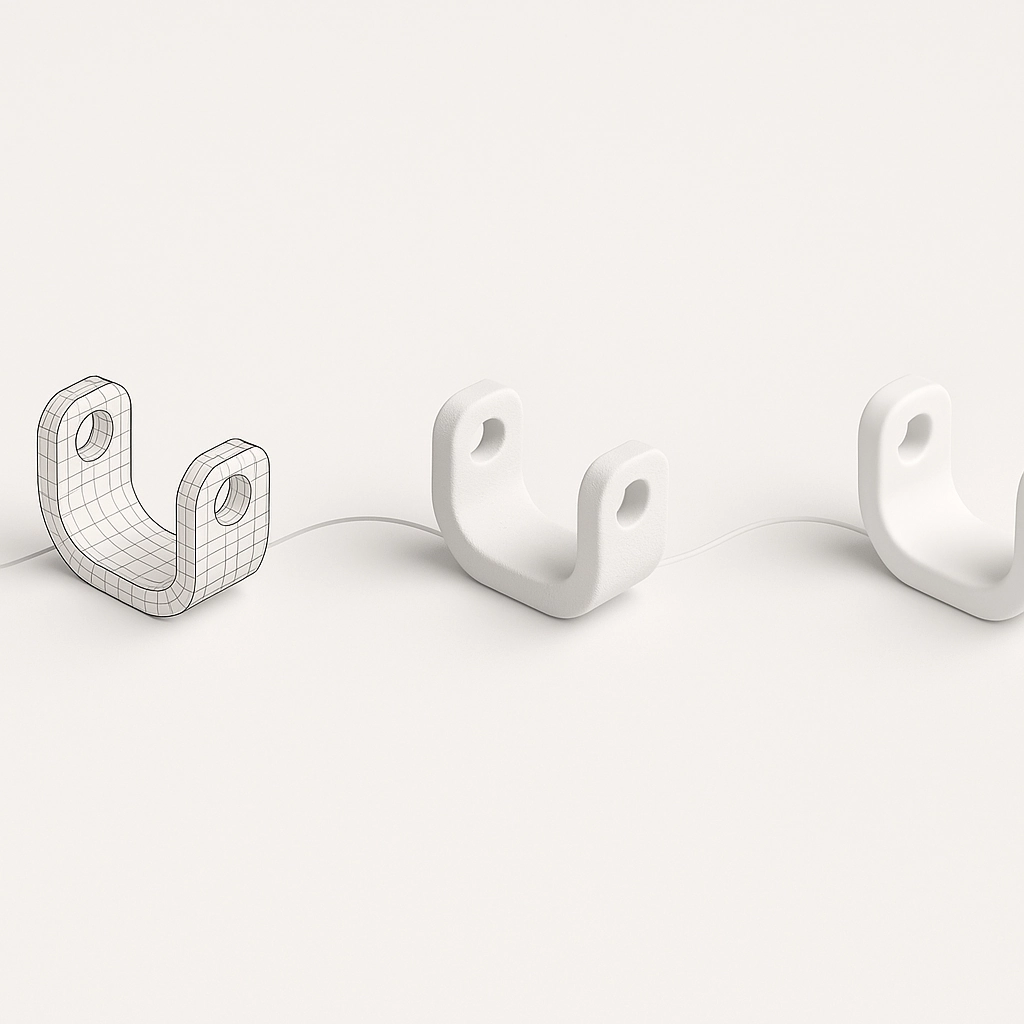

Phase 1: Strategic Prototyping

Our approach begins with strategic prototyping – not just creating a model that looks and functions like the final product, but designing with manufacturability in mind from the start.

Technology-Agnostic Prototyping

At SICAM, we're not committed to any single prototyping technology. Instead, we select the right approach based on your specific needs:

- Multi Jet Fusion (MJF): For functional prototypes with excellent mechanical properties.

- Stereolithography (SLA): When surface finish and fine detail are critical.

- Fused Filament Fabrication (FFF): Not the common desktop versions, we run industrial FFF machines– a powerful technology for fast, cost-effective innovation.

- CNC Machining: For precision components that require tight tolerances.

- Direct Metal Laser Sintering (DMLS): For metal prototypes with complex geometries.

Our additive manufacturing capabilities allow us to produce complex prototypes in days rather than weeks, accelerating your development timeline without sacrificing quality.

Design for Manufacturability (DFM) from Day One

Unlike traditional prototyping services, our engineers incorporate production considerations from the very beginning:

- Material selection that aligns with final production capabilities

- Design features that eliminate unnecessary complexity

- Tolerances that balance precision with manufacturability

- Part consolidation to reduce assembly costs

"The decisions made during prototyping set the stage for everything that follows," explains our Chief Engineer. "When we prototype with production in mind, we eliminate 90% of the issues that typically delay market entry."

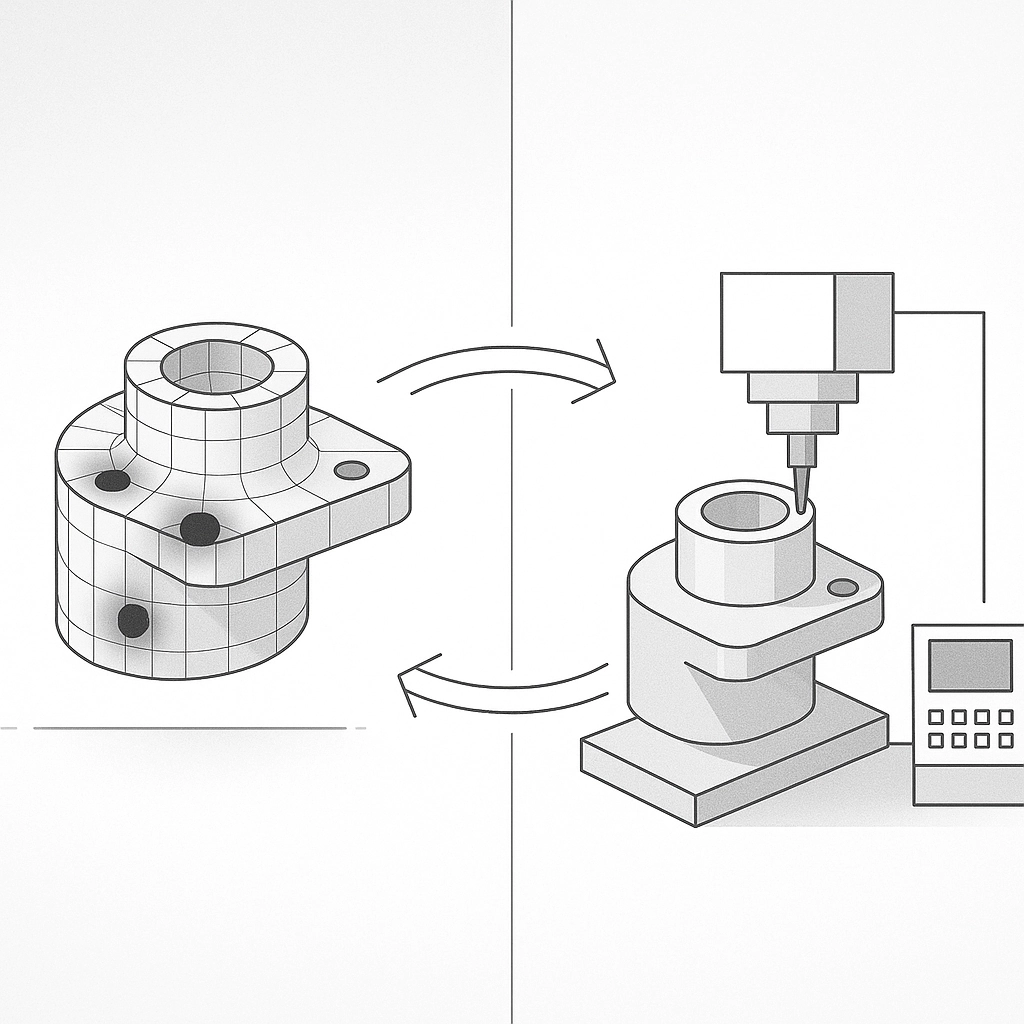

Phase 2: The Bridge – Transition Engineering

The gap between prototype and production is where most product development processes break down. Our transition engineering phase serves as the bridge, systematically addressing the challenges that emerge when scaling from one to many.

Transition Protocol

Our proprietary transition protocol includes:

- Production Simulation: We analyze your prototype using advanced simulation tools to identify potential manufacturing issues before they occur

- Material Alignment: Ensuring the materials used in prototyping have appropriate production analogs

- Tolerance Rationalization: Optimizing tolerances to balance precision with manufacturability

- Tool Pathing: Developing efficient production processes that maintain quality while minimizing cycle times

"Most companies discover production problems on the production floor," notes our Production Manager. "We find and solve them in the digital space first, saving time, money, and frustration."

Small-Batch Validation

Before committing to full production tooling, we often recommend a small-batch validation run that serves as the ultimate proof of concept:

- Validates production methods

- Confirms material performance

- Verifies assembly processes

- Provides test units for final validation

This intermediate step has saved our clients millions in avoided tooling mistakes and market delays. Learn more about our FAI+ process.

Phase 3: Scalable Production

With a validated design and production process in hand, scaling to full production becomes remarkably straightforward. Our injection molding capabilities and other production technologies are calibrated specifically for your product, ensuring consistent quality from the first part to the millionth.

Production Technologies

SICAM offers multiple production pathways, depending on your volume, material, and performance requirements:

- Injection Molding: For high-volume plastic parts with excellent repeatability

- CNC Machining: For precision components with tight tolerances

- DMLS Metal Printing: For complex metal parts that would be difficult to machine

- Hybrid Approaches: Combining technologies for optimal results

Quality Assurance

Production quality isn't an afterthought at SICAM – it's built into every step of our process:

- First Article Inspection: Comprehensive verification of initial production units

- Statistical Process Control: Continuous monitoring of critical dimensions

- Material Certification: Validation of material properties throughout production

- Traceability: Complete documentation from raw material to finished product

Real-World Results: The SICAM Difference

The proof of our approach is in the results. Here's what our integrated prototype-to-production methodology achieves:

- Faster Time-to-Market: Average reduction of 40% in development time

- Lower Development Costs: Typically 25-30% savings compared to traditional approaches

- Reduced Production Issues: 90% fewer production-related design changes

- Higher First-Pass Yield: Averaging 98% acceptance rate on initial production runs

Case Study: Medical Device Startup

A medical device startup came to SICAM with a promising prototype but faced significant challenges scaling to production. Using our integrated approach:

- We identified five design features that would cause manufacturing issues

- Redesigned critical components for manufacturability without compromising function

- Developed custom tooling that reduced cycle time by 40%

- Implemented a quality control system that ensured regulatory compliance

The result? A product that went from prototype to FDA-approved production in just seven months – half the industry average timeline.

Why the SICAM Approach Works

Our success in bridging the prototype-production gap comes down to three core principles:

- Integrated Expertise: Our team includes both prototyping specialists and production engineers working together from day one

- Technology Flexibility: We're not tied to any single manufacturing method, allowing us to choose the right approach for each component

- Forward-Thinking Design: We design with the end in mind, considering the entire product lifecycle during initial development.

Ready to Bridge Your Prototype-Production Gap?

Whether you're at the concept stage or have a prototype that's ready for production scaling, SICAM's integrated approach can help you navigate the transition efficiently and effectively.

Visit our solutions and services page to learn more about how we can help bring your product to market faster, more efficiently, and with higher quality.

The journey from prototype to production doesn't have to be a leap of faith. With SICAM's systematic approach, it's simply the next step in a well-designed process.

671